Dealer4

Construction

Dealer 4 is constructed to provide long and reliable operation. Using stainless steel as main chassis material provides robust and good looking construction. Direct drive Brushless DC and Stepper motors, ball bearings and no belts or gears provide long life and low maintenance operation. The powerful 200MHz DSP processor provides fast and accurate functionality. Full control of card movement eliminates any possibility of error during dealing leading to an incorrect board.

**errors during dealing are possible, read errors, feed card and gate errors can happen. They depend mainly on the condition of the cards. The acceptable error ratio for cards in good condition is 1 error for 100 dealt boards. These errors are reported and the machine operator can take proper action. Probability of the undetected error which can lead to an incorrectly dealt board is zero.

**regular maintenance of the machine is required. Do NOT use any solvent on the lens of the Dealer4/4+.

Sales and Support:

BridgeNZ is the official sales and support centre for the Dealer4/4+ in New Zealand and can provide assistance or servicing as required. Please call to arrange a time before sending your Dealer4 for service, and please include the power supply and at least 2 decks of average wear cards for testing and calibration.

User manuals and software updates are available for free download from the Dealer4 support site.

Contact: Please contact BridgeNZ by email or phone 027 404 4648 for any sales or service enquiries.

Specification:

Time of dealing 1 board: - 5.5s

Dealing capability: - 250-300 boards per hour

Card dimensions: - max: 91.0mm x 59.0mm

- min: 85.0mm x 54.0mm

Dimension: - 375mm x 175mm x 160mm

Weight: - 7.5kg

Power usage: - average – 20W, max – 57W

Power supply: - input (mains) 100-240V 50-60Hz,

- output (machine connection) 19V/3ADC

PC connection: - USB2.0 (compatible with USB1.0 and 1.1)

Dealer4 recommended cleaning procedure

Suggested materials

- Methylated Spirits – prefer 50% solution in water

- Lint free cloth

- Cotton buds

- Lens cap or card for covering lens on camera

Internal roller cleaning

- Cover the camera lens with a lens cap or playing card to avoid any splashing landing on the lens

- Clean the orange feed toller removing any dirt and oils from the surface and grooves. Ensure there are no hairs around the roller arm which may get between the roller and the camera.

- Remove top Perspex cover.

- In the Dealer4 programme on the computer, go to the Maintenance screen.

- Turn on the drive motors.

- Use a damp cloth to remove any dirt from both top and bottom rollers. NOTE: the first bottom roller may require the user to open the flip plate and access the roller from the first (south) pocket at the front of the Dealer4. Dry the rollers after washing with the cloth.

- After cleaning turn off the drive motors.

- Clean around the mushroom in the feed hopper, ensuring a clean path for the feeding of the cards.

- Clean off any residue that has fallen onto the base plate inside the machine.

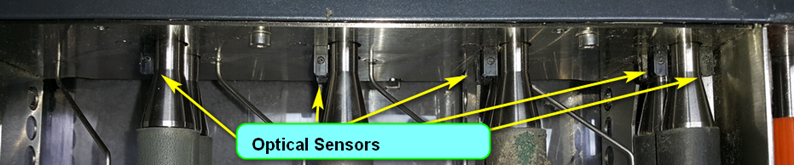

- Clean the optical sensors with a cotton bud. Ensure that there is no dirt/hair around the sensors.

NOTE: there are six pairs of sensors, 5 beside the rollers:

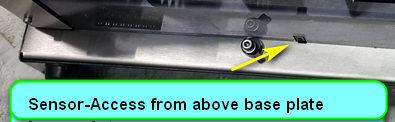

and one at the back of the base plate where the board is detected.

- Clean the top of the camera using a DRY soft cloth or cotton bud:

IMPORTANT: DO NOT use chemicals on the camera lens and do not wet the camera lens – it is a plastic lens, and any solvents will damage the lens. - Replace the top cover after ensuring that all the internal rollers are clean and dry.